The Great Valley Intersect

August 18, 2016 by Joseph

Filed under Prime Blog

Drayton Valley 1,000 m Intersect, Alberta, Canada.

During the early winter months of 2015 Precise Crossings of Spruce Grove, Alberta contracted Prime Horizontal to assist in the completion of a 1,000 meter crossing of the Brazeau River in Drayton Valley. Due to the tough ground conditions and a narrowing schedule, an intersect was decided as the best solution for completion.

Drayton Valley is located on Highway 22, or what’s locally known as the Cowboy Trail, some 80 miles southwest of Edmonton, Alberta. The historic Cowboy Trail features horseback trail rides, farm and ranch vacations, guest ranches, western themed attractions, accommodations, adventures, historic sites and western themed shopping. The valley is surrounded by Brazeau County, known for its vast oil fields located between the Pembina River and the North Saskatchewan River, just to paint a picture of the jobsite environment.

The main contractor for the project was Tourmaline Oil Corp, a Canadian intermediate crude oil, natural gas exploration, and Production Company. Precise Crossings filled the roll of trenchless contractor, utilizing their 40+ years of experience in the Horizontal Directional Drilling industry.

The project’s consulting engineer, planning, and supervision was undertaken by CCI Inc., a leading expert in Horizontal Directional Drilling (HDD), Open-Cut and Micro-Tunneling methods since 2004.

Prime Horizontal was selected for the project due to extensive knowledge of wireline guidance and horizontal intersects along with demonstrated ability to surmount the obstacles that were expected when carrying out a drilled crossing of the Brazeau River.

One obstacle was ground conditions, which included variations of gravel and sand on both entry and exit side. This formation contributes to difficult fluid control, troublesome steering and poor hole sustainability.

The project managers, based on their local knowledge of the potential difficulties and prior to commencing work, both for the planning stage and practical contracting purposes, carried out ground investigation works to best identify the formations to be drilled for planning purposes. Geotechnical holes were drilled on both entry and exit sides showing the depths of the gravel seams. To help alleviate the ground condition issues on the entry side, 25 meters of casing was required, and on the exit side 45 meters of casing was used.

The difference in length was due to the exit side elevation being substantially higher. The casing would prevent the flow of returns and constant working of the drill string from disturbing layers of sand and gravel resulting in potential hole collapse and increased annular pressures. It also does not allow the assembly to deviate from the already drilled hole when tripping in and out.

In addition to casing, Precise Crossings proposed doing the installation with two smaller rigs and performing an intersect in order to manage fluid pressures more effectively. Smaller rigs using smaller mud motors require less mud volume and pressure to drill than their larger counterparts, resulting in their choice for this project. A drilled intersect allows two smaller rigs to span the length of the same crossing in an acceptable time frame. Maintaining drilling fluid returns for the overall distance of the entire bore is made simpler since only half of the total distance is required from each side. Overall fluid velocity remains higher, annular pressure stays lower thus formation cuttings stay suspended in each hole.

The rigs that were utilized on both entry and exit side were American Augers DD-110 rigs. Precise Crossings had a custom made mud system with Derrick Hyperpool Shakers and Gardner Denver mud pumps on each end of the intersect. The Down Hole Assembly was a 7 7/8” Tricone TCI bit on a 4 ¾” mud motor. The pipe pulled was an 8” steel product line.

The ParaTrack-2 AC Guidance system with the Rotating Magnet Ranging System was chosen and used to intersect the two drills. Rotating Magnet guidance was used because the project timeframe was rushed and needed to have the best chance of intersecting on the first attempt as road bans were imminent and moving heavy equipment would not be possible if intersect operations took too long. The ParaTrack-2 Rotating Magnet Ranging System offers ranging accuracy that is unparalleled by other passive magnetic downhole ranging products.

Results from the RMRS system can be well modeled with up to 40 meters of separation, where Passive Magnetic systems struggle beyond 4 meters. At close range the RMRS resolution is more enhanced, supplying operators with better data to make more accurate steering decisions.

The rig on exit side was mobilized first and drilled 480m of the pilot hole, and then reamed up to 14 inches in diameter. While reaming was taking place on the exit side, the entry side rig started drilling their pilot hole towards the exit side. Upon completion of the exit side reaming, the rotating magnet was tripped into the exit side to begin the intersect procedure.

The entry side drilled up to the end of the exit sides bore at about the halfway point of the crossing. On March 8th the first ranging pass-by was completed showing a lateral separation of only one meter and another meter vertically. The gap was closed over the course of 60 meters in a 12 hour shift and intersection was accomplished at around noon on March 9th. Once the intersect was performed, both rigs tripped out of the hole and the entry side began forward reaming to 14 inches in preparation to pull pipe.

Precise Crossings mobilized on February 6th, consequently completing the pilot on March 9th, hence the pipe was pulled on March 14th, thus making this project a success. Prime Horizontal was mobilized for guidance of the exit side on the 28th of February; intersect operations commenced on the 8th of March and successfully concluded on the 9th of March, 2015.

– Article written by C. Joseph, J. Teer and S. Teer, Prime Horizontal Group of Companies

Our Crossings and Intersects (with ParaTrack)

August 9, 2016 by Joseph

Filed under Prime Blog

Prime Horizontal’s success was initially based on the development in 1998 -1999 and successive improvements of the ParaTrack system of horizontal guidance. Originally developed by Vector Magnetics as an underground parallel-drilling location system, the ParaTrack system was co-developed and continues to be improved by Prime Horizontal and Vector Magnetics for specific application to the HDD market.

Steering of the drill bit is performed by first measuring the location of the drill bit relative to its planned track using magnetometers and accelerometers in the ParaTrack steering tool. The magnetic field from an external magnetic source, typically a large coil of wire through which is passed an AC electric current (ParaTrack-2) or a DC electric current (ParaTrack-1), is measured at the steering tool with the magnetometers in the tool and the location relative of the drill bit is computed and passed to a display unit in real time so the driller can adjust the drilling parameters to stay on track. Additionally, wireless AC sources give the necessary precision of plus or minus a few centimeters to complete intersect crossings underground, and ParaTrack-2 is the only steering system today capable of measuring and analyzing AC magnetic fields.

Magnetic sources include both wire-based coils and non-wire based magnetic sources with the ParaTrack-2 system, including the Axial Magnet sub, the Rotating Magnet (RM) Sub, the AC Beacon, and the AC Benchmark making possible many new steering applications, especially for the completion of intersect crossings requiring maximum precision where the crossing is completed entirely underground with the intersection of two drill bits, one drilling from the entry side and the other drilling from the exit side.

With the addition of the Pressure While Drilling (PWD) Sub to the drill string, ParaTrack-2 also measures pilot-hole annulus and internal pipe pressure at the steering tool.

We have used ParaTrack-2 in the freeze drilling of tunnels. Freeze drilling is a technique used in the tunnelling industry when the tunnel must be bored in soft, unconsolidated sediments which collapse as the boring operation takes place. To prevent this collapse, many small, parallel bore holes are made through which is circulated a slurry of freezing brine. After the surrounding formations are frozen solid, the boring operation can continues to completion. The tolerances are very small for the brine holes and the ParaTrack-2 system meets these tolerances when used with the MicroCoil magnetic source (the Naples Metro project} and with the Rotating Magnet source (the Hallandsås Rail Tunnel project still ongoing).

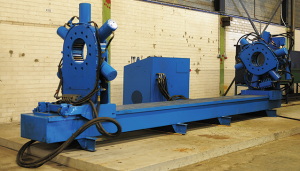

For rent/sale – Mobile Breakout Units

January 27, 2016 by Joseph

Filed under Prime Blog

https://primehorizontal.com/drilling-tools/mobile-break-out-unit

We are proud to announce that we have breakout units available. Either rent or sale for placement at the customer’s drilling site. The breakout units are available for both sale or rental basis. The break out unit is completely mounted in a container transported to the drill site by truck or by boat. It handles strings of 2 7/8″ diameter to 14 1/4″ pipe with up to 70,000 ft-lb of make/break torque with a mud rotor extractor of 23,000 pull force at 3,350 psi.

Among the many possible uses for such a mobile break out unit is the overhaul at the drill site of downhole mud motors without having to return the motors to home base, saving time and money.