ProData

Whether you operate a single horizontal directional drill or a whole fleet of drills, you need to keep your investment working for you 24/7.

And you don’t like breakdown surprises.

Check out Prime Horizontal’s ProData System.

A communication gap often exists between on-site operations and office management in the horizontal directional drilling (HDD) industry. This gap can be caused by a lack of detailed communication or by delays in relaying key information from rig site to office.

End users and drilling contractors are now appreciating the benefits of using ProData, Prime Horizontal’s rig data recording and transmission system which gives field and office personnel immediate access to measured drilling parameters during the drilling process.

ProData, custom designed and purpose built specifically for the HDD industry is a cost effective system for measuring drilling parameters and displaying them at the rig site and remotely via an internet connection.

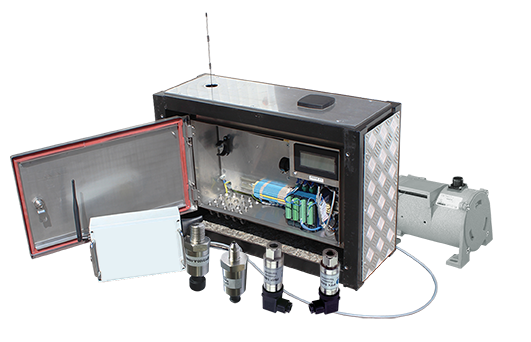

The basic system consists of a sensor package for drilling parameters utilizing off-the-shelf Hall Effect switches, rotary encoders, pressure sensors and non-contact sensors.

The basic system consists of a sensor package for drilling parameters utilizing off-the-shelf Hall Effect switches, rotary encoders, pressure sensors and non-contact sensors.

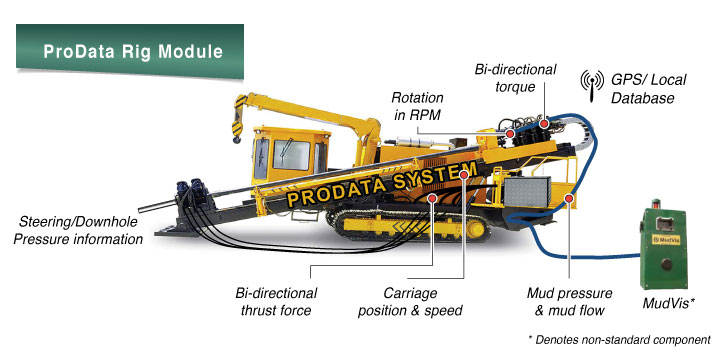

In addition to the basic package it is possible to integrate the Prime Horizontal MudVis system or connect a steering tool during pilot operation for logging of basic downhole information. The system is permanently installed on your drilling rig and is mounted inside a robust enclosure either on the drilling rig or in the drill cabin. The ProData system records its own GPS position.

The ProData system automatically gathers, stores and transmits it modular suite of HDD rig site data to an on-site database (Local). The data is also transmitted via the cell network to the Prime Horizontal cloud-based database (Remote). Both remote and local database archives make all logged data available for on-demand access by means of the intuitive and user-friendly client access portals. Through these portals the customer gains access to either historical or “live” data (near real time) from one of the two Prime web servers.

A Daily summary report is generated automatically by the system in PDF format. This report contains a review of the days drilling and includes such parameters as rig hours, pump hours and average rotational speed. The system can be configured to email this report automatically to a defined list of email addresses.

The ProData System Uses

- Retrofit existing drill rigs or install on new drill rigs

- Suitable for installation on drill rigs from 12 to 600 tons

- Use of field proven and internationally certified sensors

- Use of modular design for adding new data packages, such as steering data, mud weight & viscosity data

- GPS Position tracking

- Use of wireless technology to avoid using cables at the drill site

- Ruggedized and reliable against vibration and ingress to minimum IP67

- Automatic data transfer to local and cloud-based user portal

- Security with password access for each rig and each client

- Capability of multiple users per client with client definable user permissions.

The ProData Rig Module Basic Package

- Carriage Position

- Carriage Speed

- Push

- Pull

- Torque Clockwise and Counterclockwise

- Drill Head Rotation (RPM)

- Mud Pressure

- Mud Flow

- Steering data (ParaTrack)

*Custom measurements are available upon request

**Measurement units are as specified by client

ProData Benefits

- Reduce downtime

- Reduce broken pipe and stuck pipe problems with:

- High and low alarms of all measured drilling parameters

- Real time graphical representations of drilling parameters measured every 3 seconds

- Increase Tooling Life

- Increase Production

- Increase Predictability

- Increase Profitability per rig

- Improved cost/benefit

- Data Archive ON and Off Site

- Multiple Rigs, multiple access permissions, all password protected with high level of security