HDD Coal Bed Methane and RMRS

The HDD RMRS System and the production of Coal Bed Methane

In recent years, the production of coal bed methane (CBM) with a combination of vertical and horizontal wells has become cost effective, especially when used with HDD methodologies. See FAQ #9 for a discussion of Coal Bed Methane and FAQ #10 for a discussion of Drilling for CBM.

Accurate horizontal to vertical well intersections

The Rotating Magnet Ranging System (RMRS) system as supplied by Prime Horizontal is a cutting edge magnetic downhole ranging system for use in Vertical – Horizontal and Horizontal – Horizontal well intersects. When being used for a Vertical – Horizontal well intersect the particular advantage it has over all other technologies is the ability to locate the drilling assembly up to 60m before the intersect point has been reached. This enables the necessary changes in direction to be made before reaching the intersect point and increasing significantly the possibilities of a successful intersect on the first attempt.

All other current downhole ranging technologies rely on the use of a “pass-by”. To perform a pass-by the downhole assembly in the horizontal well must be drilled past the vertical well to locate it. Once the horizontal well has been located it must then be pulled back and sidetracked for a second attempt. This loses time, and can also introduce hole quality issues. Being able to range directly to the bit significantly increases the possibility of a first time intersect. Success rates for first time CBM intersects run at around 90%.

Smart tools, precise and efficient operations, proven results

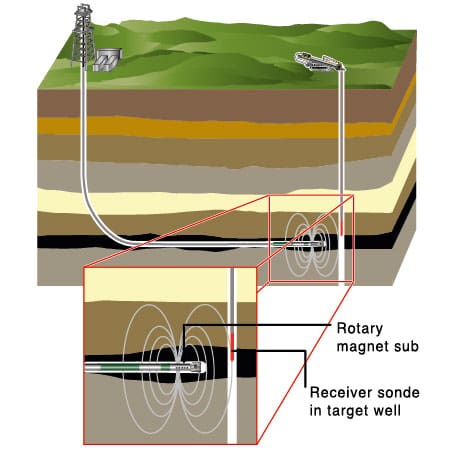

Prime Horizontal’s RMRS system is unique in its design and its ranging precision. It uses a near-bit sub that has a number of magnets aligned in the sides of the sub. When the bit spins, the magnets create an AC magnetic field which can be detected from a reasonable distance to allow correction of the trajectory to allow vertical well intersection without doing an initial ranging pass by as required by all other technologies. This geometry is diagrammatically shown in the photo and the RMRS sub is shown in the diagram.

The signal can be detected from 50-60 m away and a corrected vertical target location can be calculated. This technique is different from the technique using a single wire conventional HDD source, where the steering tool is located in the vertical well above the drill bit, because the rotating magnet at the bit is the source and the steering tool is located in the horizontal well. The steering tool works independently of the MWD system used in the drill string. The rotating magnet has minimal effect on the magnet field of the MWD tool as it is located far behind the motor with adequate spacing. If the directional driller has concerns about the interference then a full drilling assembly roll test can be performed to calculate the magnetic flux from the drilling assembly.

| Technical Specifications | |

|---|---|

| Nominal Tool OD | 44.45 mm |

| Minimum Target Well ID | 50.8-22.2 mm |

| Sonde Length | 1.4 m |

| Weight Bar Length | 1.2 m |

| Centraliser Length | 0.4 m |

| Typical Length of Assembly | 3.4 m |

| Magnet Bit Sub Connections | 2-3/8" Reg and up |

| Operating Temperature Range | 85ºC |

| Max Operating Pressure | 1034 bar |

| Accuracy 0-15m | 2-3% |

| Accuracy 15-25m | 2-3% |

| Accuracy Beyond 25m | 5% |

| Max Operating Range | 70 m |